PRODUCTS

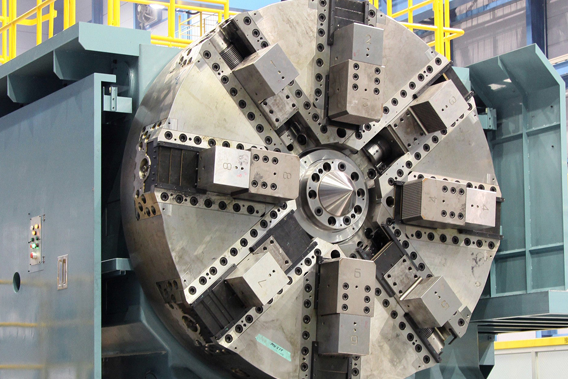

Turbine Rotor Lathe

Roll Lathe

Two Way Bed Lathe

Turning Center

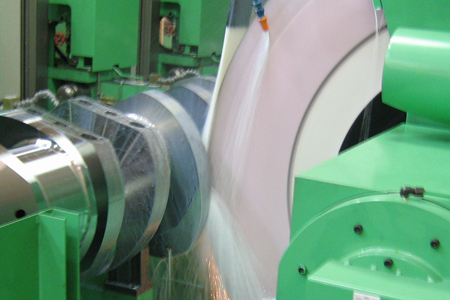

Roll Grinder

Crankshaft Grinder

Work Traverse Roll Grinder

Gear Skiving Machine

Gear Shaper

Gear Hobbing Machine

Worm and Thread Grinding Machine

「Build to Order policy」

On standard design basis Karats customizes designs complying with requests, which has formed a key tradition of Karats products.

Such tradition is unique in mass production minded machine tool building industry.

Hearing a request, presenting an idea and modifying the idea through discussion are the essential course to finalizing specs and designs.

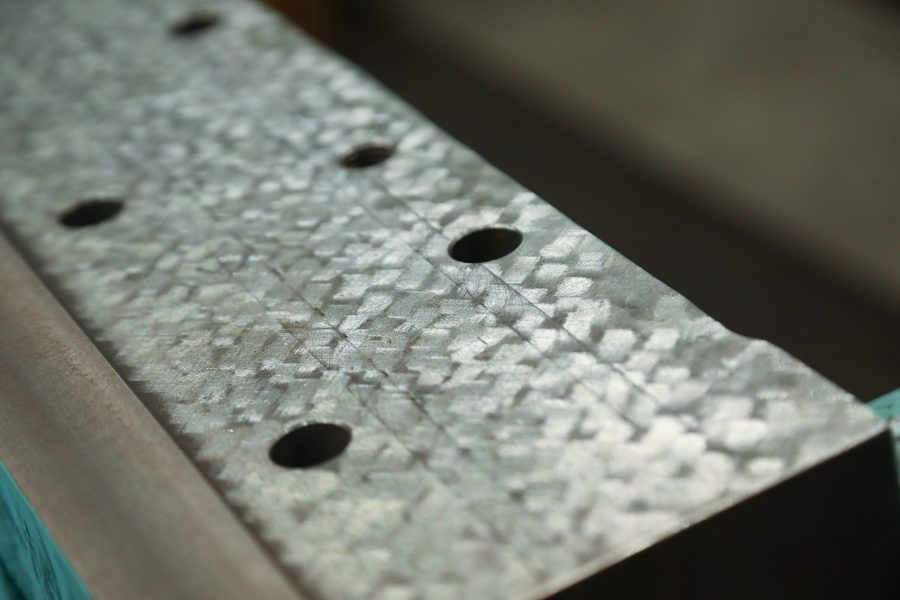

「Hand Scraping」

Hand scraping is a traditional skill used for excellent surface finishing instead of finishing by machining.

Highest flatness and straightness are available by hand scraping, which is the best for highest quality fitting use and sliding use.

High quality fitting and sliding are the keys for the long time machine function and precision warranty.

Karats has applied the skill for decades and most of Karats assembly men are skilled in hand scraping and apply the skill for bed slide way finishing and small parts fitting.

「Match Machining」

Match machining is not widely used now, but Karats still applies the skill for some limited nos. of parts where only few micro meter fitting play is required.

It’s time and labor consuming, but Karats judges them indispensable.

「Measurement」

High precision measurement is the mother for high precision machining and assembling.

In process and post process measurements are carried out by machining and assembling engineers in each stage, which is finally tested and assured by inspection engineers.

High precision gear tester, TFT analyzer, roundness tester, laser measuring instrument, etc. are used.

Among them, skill and facility are best prepared for gear testing.

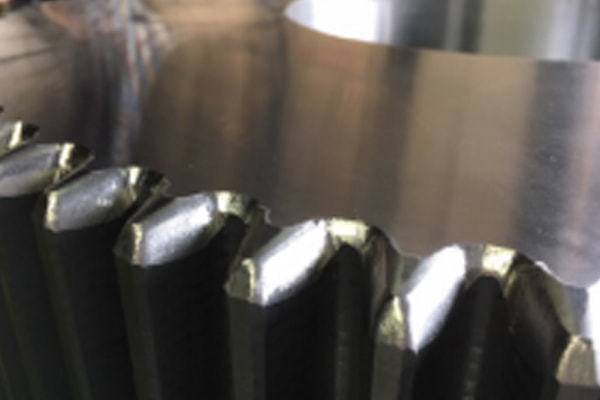

「Gear edge chamfering and rounding」

Gear edge chamfering and rounding is one of scrupulous measures of Karats way of machine tool building.

It is applied for headstock gear train which has multi-speed ranges and a range is shifted to another by changing a mating gear automatically.

For making the changing most smooth and sure, Karats applies gear edge rounding in addition to chamfering, which is unique but judged essential.

The rounding used to be a full hand work, but is now a full robot work. Technology develops, but Karats way stays.