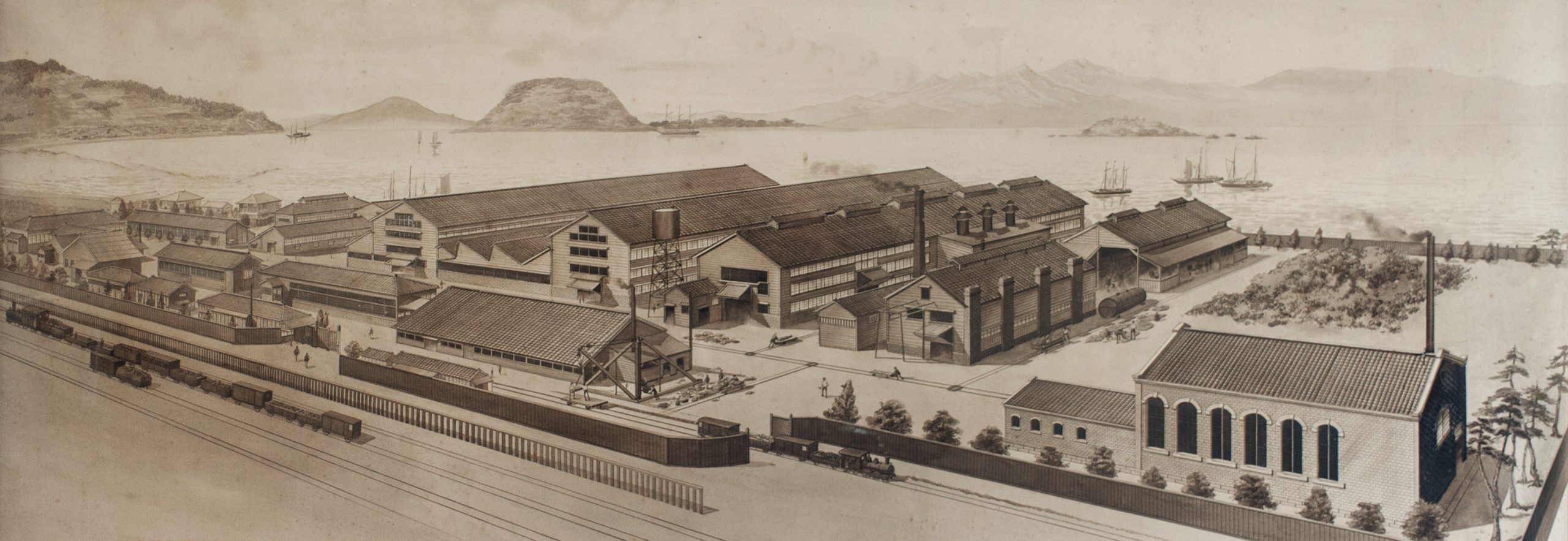

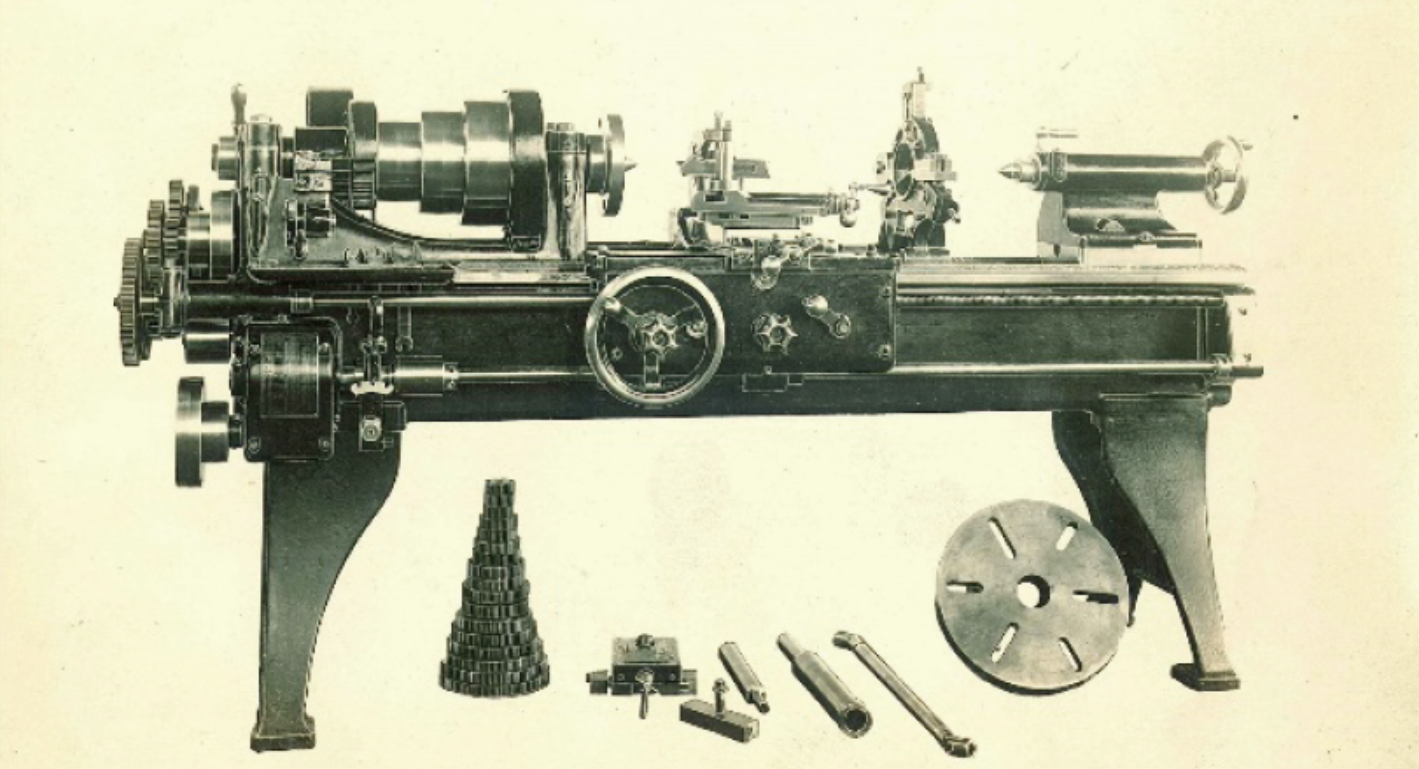

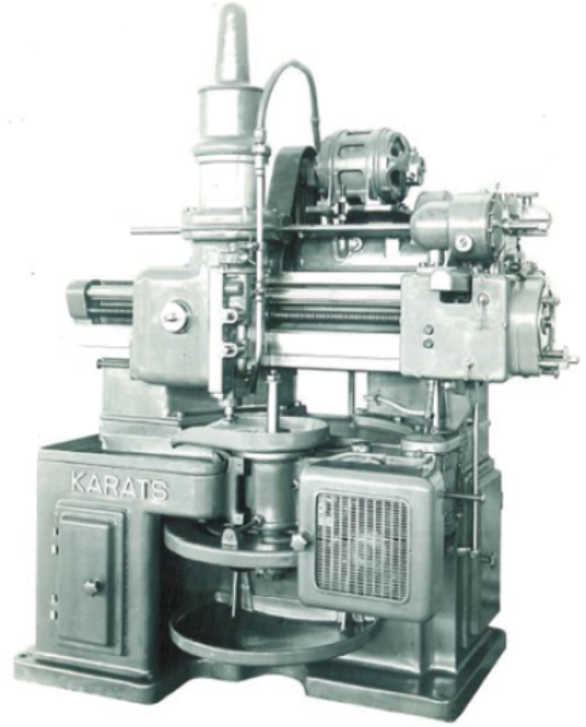

”Industry is the foundation of a country.” was the philosophy of Mr. Meitaro Takenouchi who founded Karats Iron Works as a machinery building division within his coalmine company in 1909. Among various machinery production they started building machine tools and succeeded in marketing 14 inch swing lathe in 1911 as an initial product.

After split from coalmine company in 1916, ”Karats Iron Works, Ltd” was organized by President Mr. Toshisuke Takeo who then gave whole of his life for building qualified and sophisticated machine tools until his resignation in 1955.

He also succeeded in training top-class design engineers and many skilled shop workers, then the team established the brand name ”Karats” as one of the top machine tool builders in Japan.

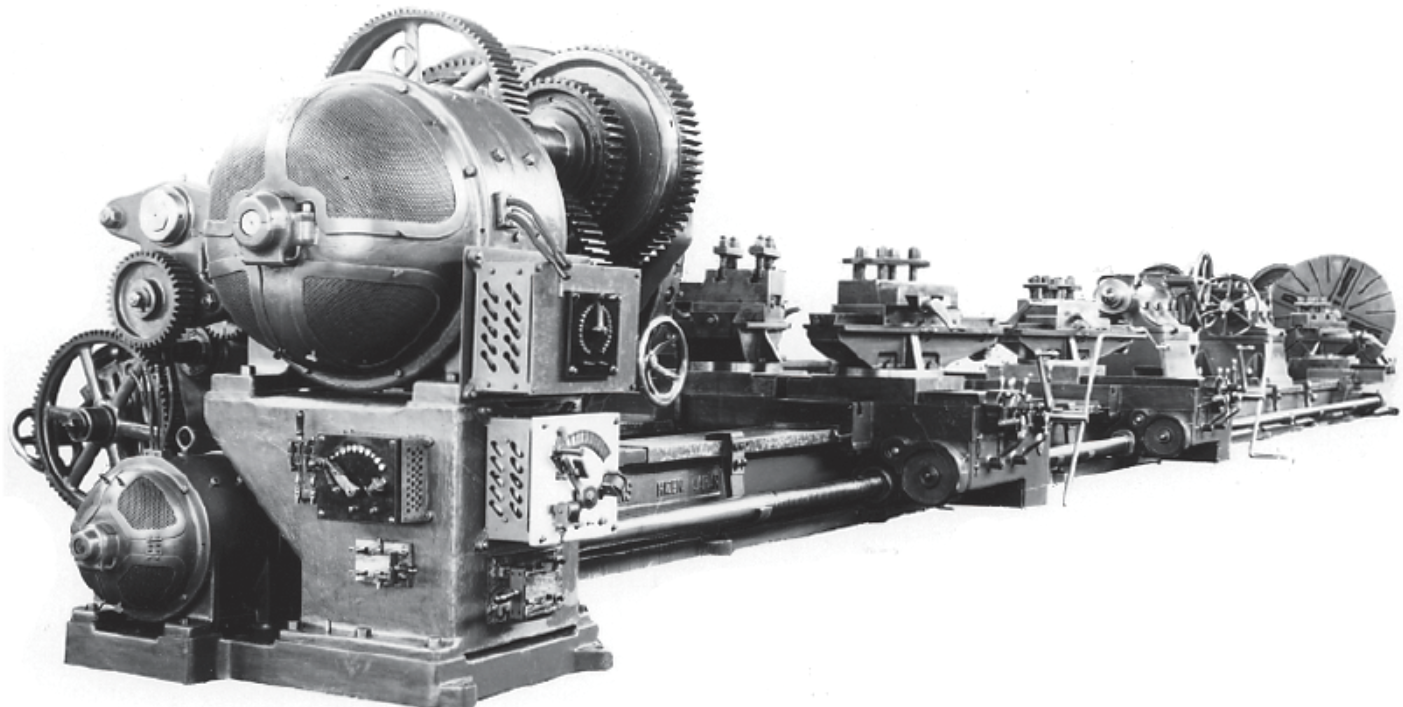

During the war Karats was fully employed as a key supplier, above all for navy use machine tools.

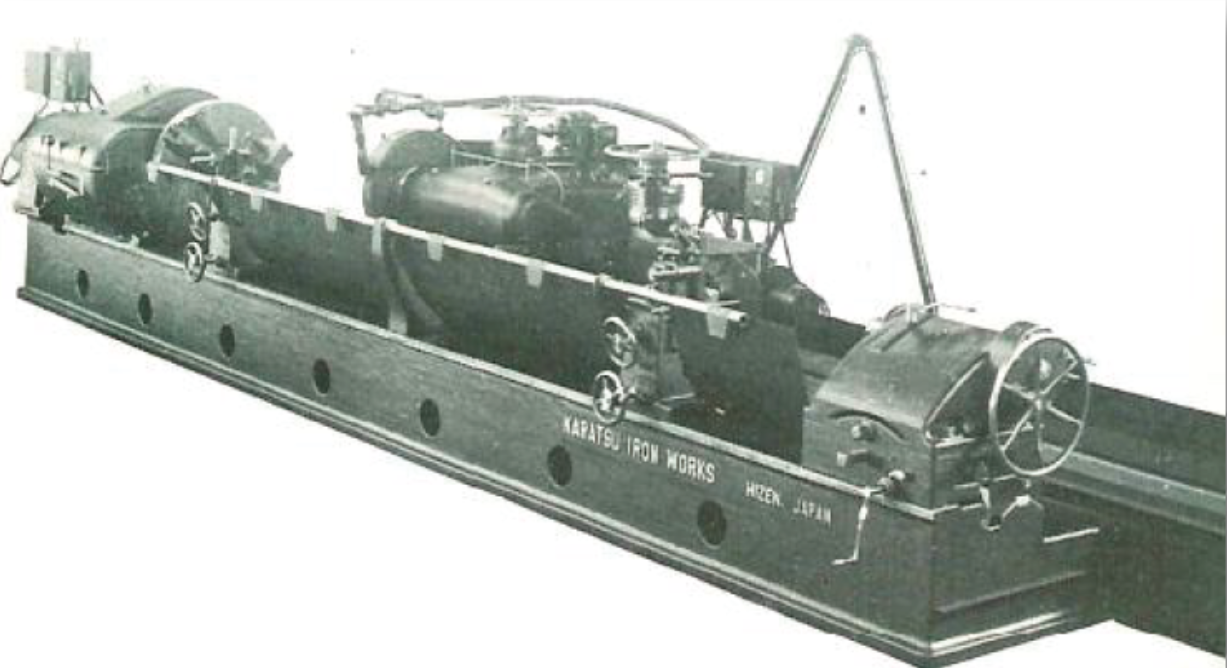

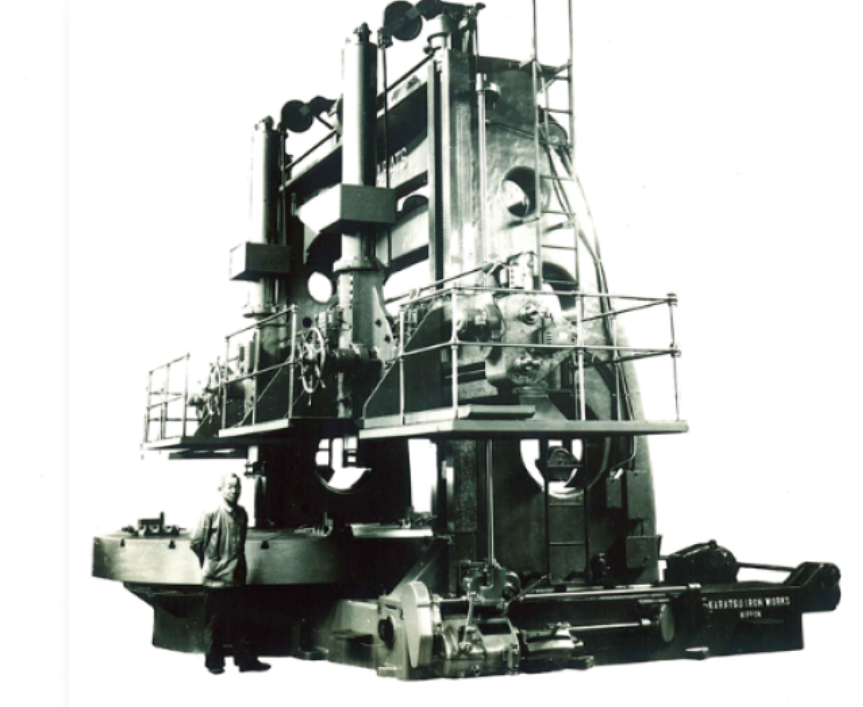

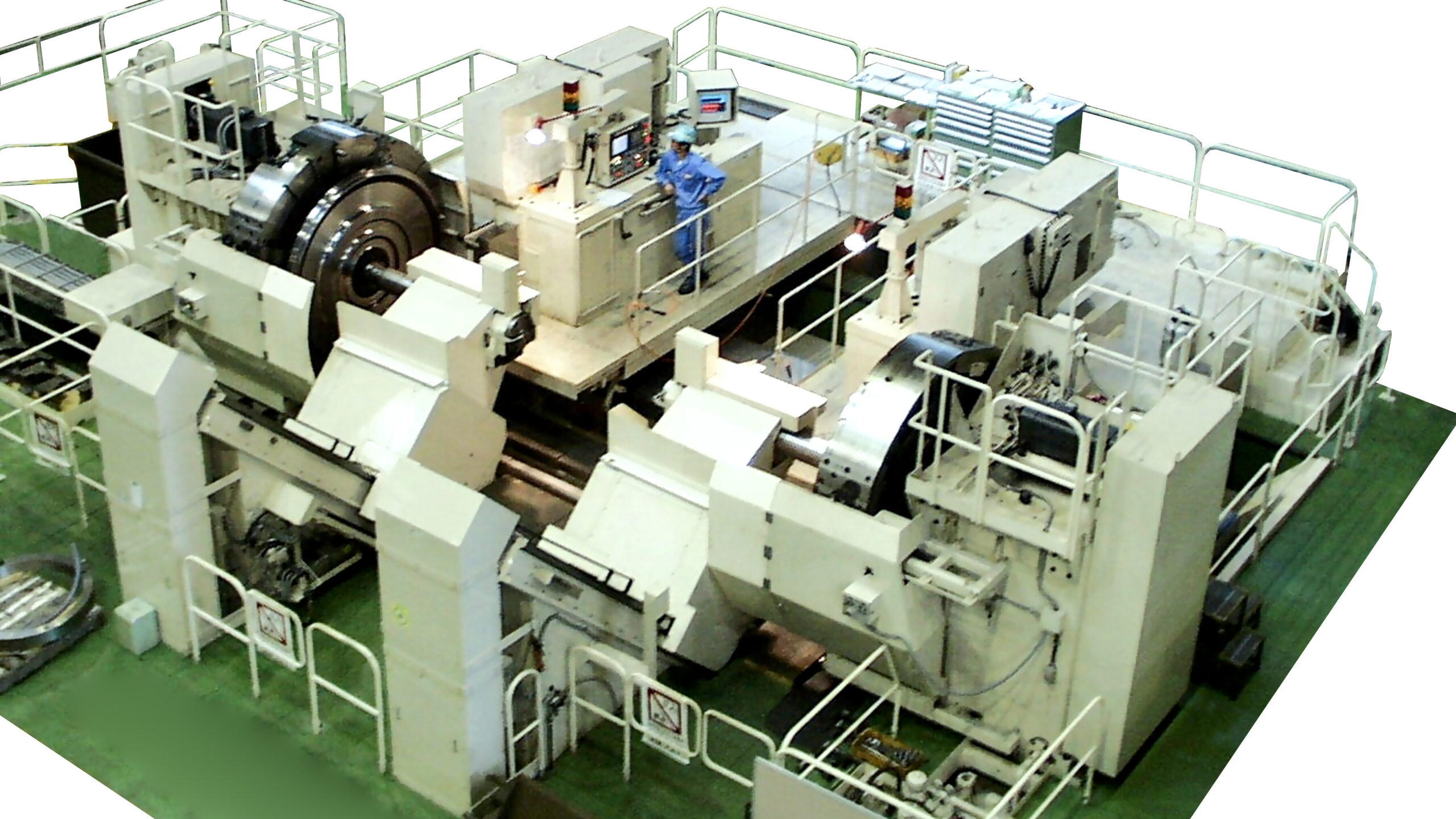

A 64m long giant gun boring machine installed in navy machining plant in 1938 for boring 18inch (45.7 cm) × 20meter bore for battleship ”Yamato” was one of the typical monuments.

In postwar to now machine tool industry has recovered and remarkably developed along with the quick and wide recovery and development of such industries as steel making, ship building, electrical appliances, heavy electricals, railway engineering, car industry, semi conductor and robotics.

Karats has recovered along with them above all in two categories, heavy machine tools (horizontal lathe and grinder) and gear technology machines, both of them are the core technologies of today’s Karats.

One of the typical developments is the successful overseas marketing.

In 1970s to Korean market, 2000 to US market, 2016 to Chinese market, in addition received many orders from India, Australia, Romania, Taiwan, Brazil, etc. Karats will advance in product development, in global marketing, in production engineering and karats will implement those plans under the motto established at time of company foundation,

”make what is profitable to use, not make what is profitable to sell”.

Karatsu Iron Works was established as a division of Yoshinotani Coal Mine, Ltd.

Our first Machine Tools was built

A Gun Lathe which performed turning and boring in the same machine

Karatsu Iron Works, Ltd. was established

(was separated from Takeuchi Mining, Ltd.)

Opened Tokyo Sales Office and Osaka Sales Office

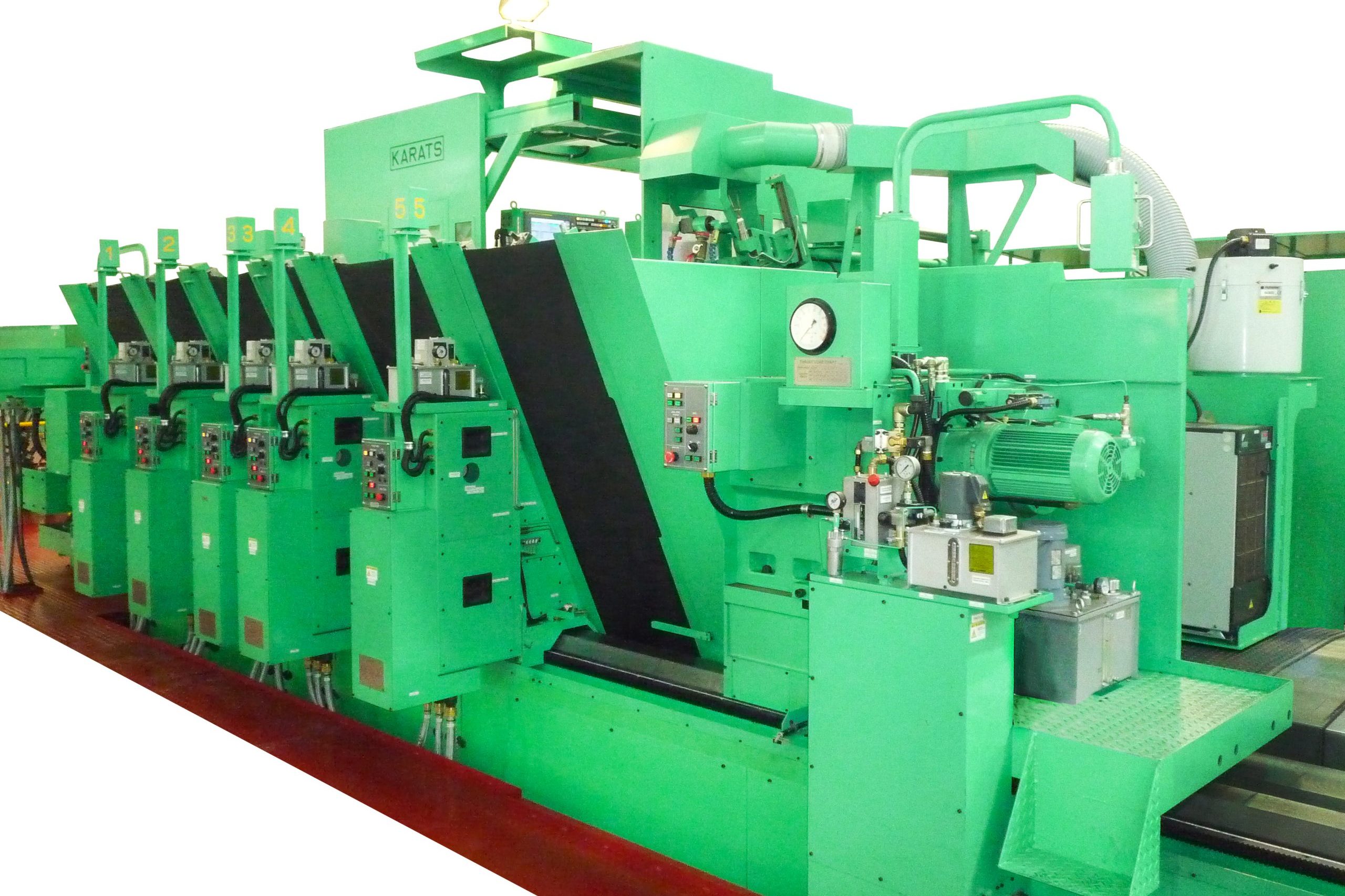

40″ Roll Grinder was built as the first domestic Roll Grinder

An extra-large Gun Boring Machine for the Battleships Yamato and Musashi

Gear Shaping Machines were developed under Japanese government special orders.

The first domestic Gear Shaper

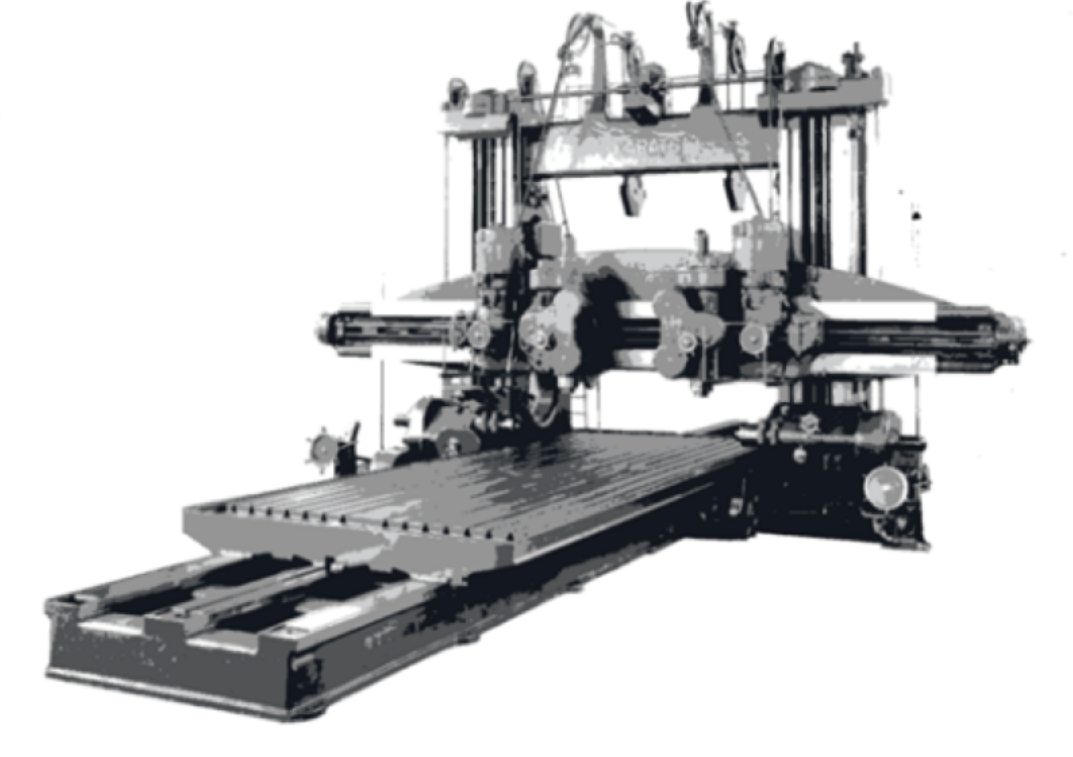

An extra-large Plano-Milling Machine was developed for Diesel Engine Casing production. It was the world largest class.

This Plano Milling Machine was awarded the Best Technical Prize by the Society to Honor Machine Tools of Historical Value.

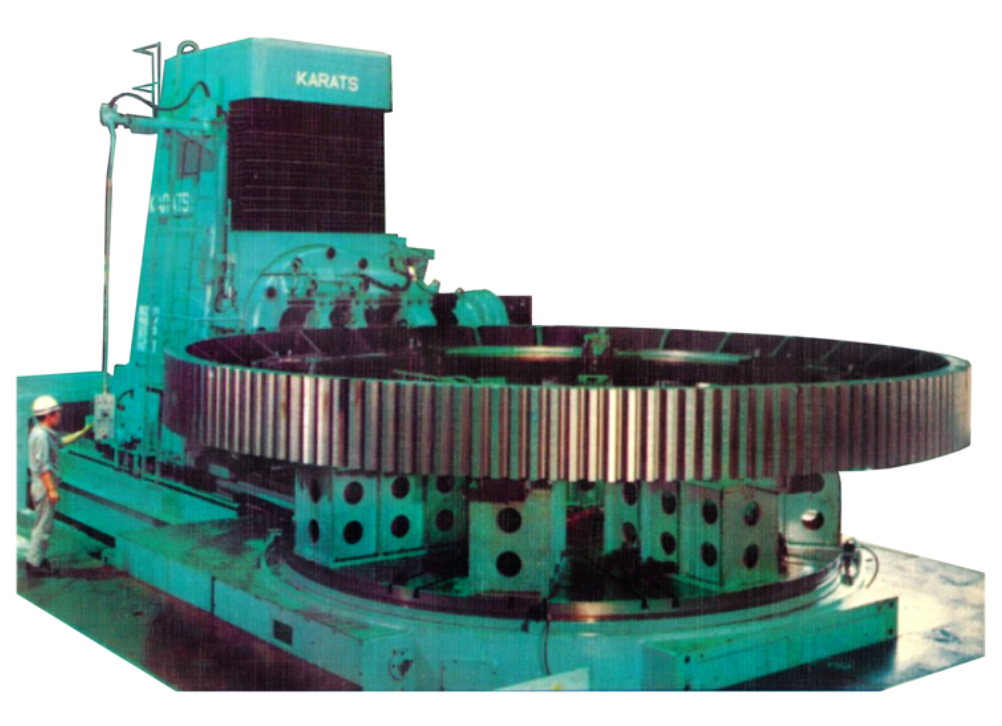

A vertical Boring and Turning Mill of the world largest class was built to produce Large Turbine Rotors for Hydroelectric Power Station Generators.

We had a honor to have a visit of Emperor and Empress Showa.

His comment was;

“I expect all your employee to unite firmly and to build excellent products because they have very important mission to lay all industries foundation.”

Our first NC (numerical control) Lathe was built.

A world largest class Universal Gear Hobbing Machine was built.

A high-speed 250mm Gear Shaping Machine was built for automotive and motorcycle industries.

A Gear Forming Grinder was developed

Assembly Building was renewed

A dedicated Large Lathe for Turbine Disc was built

A Crankshaft Lathe was developed which turns Pin and Journal in the same setup.

A Worm Gear Grinding Machine for Electric Power Steering System Component was developed and included in our product line-up.

An Orbit Type Crankshaft Grinder featured Linear Motor was developed and included in our product line-up.

Large Machine Building was completed

Canteen Building was completed

A subsidiary company was established in Shanghai, China.

A Gear Skiving Machine was developed and included in our product line-up.

The company was renamed into Karats Precision, Inc.

Japan’s largest class Gear Shaper was built.